Omega 3

Eicosapentanoic Acid Ethyl Esther

Icosapent Ethyl

CAS number: 86227-47-6

Axplora has a wealth of expertise when it comes to purifying omega 3 by chromatography at production scales. We can provide time effective development & scale up services, and cost-effective purified and ultra-purified omega-3 ingredients, such as generic EPA and other proprietary omega 3 based APIs.

A recognized expertise in the purification of Icosapent Ethyl

Axplora is a renowned manufacturer of omega 3 and other poly-unsaturated fatty acids (PUFAs) with more than 30 years’ experience in cGMP production:

- A demonstrated expertise in omega 3 purification

- A world leader in large-scale purification of omega 3 APIs, including EPA

- >1000 tons of commercial APIs produced – 100% compliant batches

- Cost-effective and environmentally friendly, patented process enabling the recycling of >99.97% of organic solvents

- Outstanding regulatory & quality assurance track record

- All our sites are regularly inspected by the US-FDA and European authorities

- Proven track record on purification process validation

- A reliable partner for omega 3 API manufacturing

- > 10 years average relationship length with key customers

- Strong commitment to sustainable and cost-effective processes

- Agile and responsive teams

- The largest high pressure chromatography plant in Mourenx, France, for large-scale purification of omega 3

- Ability to combine appropriate downstream processing steps, including High- & Low-Pressure chromatography

Our solutions for Omega 3 API purification

Axplora benefits from extensive experience in handling and purifying omega 3 from various biomass sources including fish oil, algae, etc.

Our product capabilities include:

- Highly purified EPA – Eicosapentaenoic acid ethyl ester / Icosapent ethyl (>96%)

- Highly purified DHA – Docosahexaenoic acid (>95%)

- High purity EPA/DHA mixtures at any targeted ratio

- Other fatty acids (omega 6, 7, etc.) and derivatives generated by semi-synthesis.

We offer unique cGMP manufacturing services for omega-3 and other poly-unsaturated fatty acids and derivatives, from pilot to very large-scale.

- Process development

- Process development and optimisation adjusted to your omega 3 profile requirement

- Analytical development

- Regulatory support

- Manufacturing

- Routine production

- Continuous improvement

- Life cycle management

Cost effective and sustainable manufacturing process

Thanks to a proven project management methodology, we adapt and optimize the whole process to deliver your product at the right specifications at the right time, in a cost-effective and sustainable way.

Our unique, patented solvent recycling technologies enable us to recycle up to 99.97% of solvents, leading to a significant reduction of costs of goods. We also maximize the lifetime of chromatographic stationary phases to provide more sustainable processes.

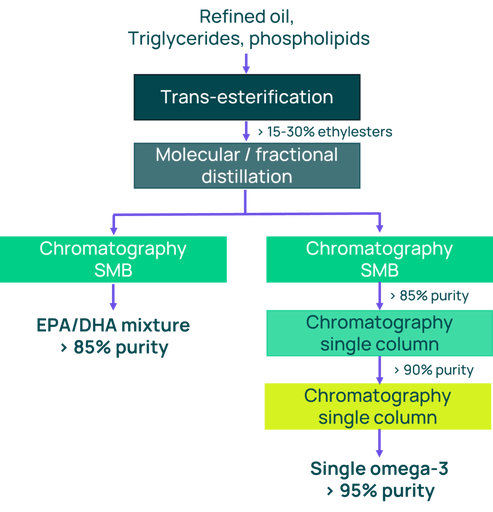

You can see below a typical example of manufacturing process for omega 3 API conducted by Axplora’s team:

Our sites involved in omega 3 API manufacturing

According to your needs and the quantities of unsaturated fatty acid you would like to produce, we operate several manufacturing facilities with adapted utilities and infrastructures:

Our Pompey site, in France, for process development, pilot and moderate-scale productions. Pompey is the center of excellence of Axplora for industrial chromatography.

With HPLC and Varicol®* continuous systems from 5cm to 45 cm internal diameter, operating at up to 100 bar, the site is equipped to produce from a few kilos to few tons.

Our Mourenx site, in France, for large-scale productions, from 10’s to 100’s tons.

Our Mourenx site is home to the largest cGMP purification plant of ultra-purified omega 3 and poly-unsaturated fatty acids in the world, with Varicol®* continuous chromatography and CyclojetTM* single column chromatography technologies, developed by Novasep.

Systems are equipped with 120-cm diameter columns, operating at up to 60 bar. The unit is equipped with advanced technologies to avoid any contact with air or light, from the crude material to the highly purified API, maximizing its stability and shelf life.

-

Therapeutic area

Cardiovascular

Hypertriglyceridemia -

Monograph

> 97 % EPA

API quality - Available grade LIQUID

-

Regulatory documentation

US DMF

CA DMF

EU DMF** - Produced in MRX